About APEL Extrusions

APEL Extrusions Limited is a market leader in high-performance manufacturing through superior customer service, continuous improvement, and safe, environmentally-sound operations. We continue to effectively meet the current and future requirements of our customers, shareholders, employees, and other stakeholders.

Our Mission

Our success is contingent upon providing products and services that enable our customers to be successful. Knowing and understanding their specific needs, goals, objectives, and future plans are critical to growing with our customers and to creating value over the long term.

High Performance

Continuous improvement is an ongoing process at APEL that we achieve by seeking out the best practices, equipment, and people to do the job. Our facilities are new, modern, and well-equipped in order to serve our customers. Safety is paramount and we keep up-to-date with assurance initiatives as we continue our quest to manufacture better, improve our quality, and respond quicker to market demands.

Our Customers

Our world revolves around our customers and quality is not a department, but a way of doing business. Building strong relationships with our partners has always been our goal. By interacting with customers on a regular basis, we know their products and needs, giving us a deep understanding of each customer’s end-use application.

APEL’s History

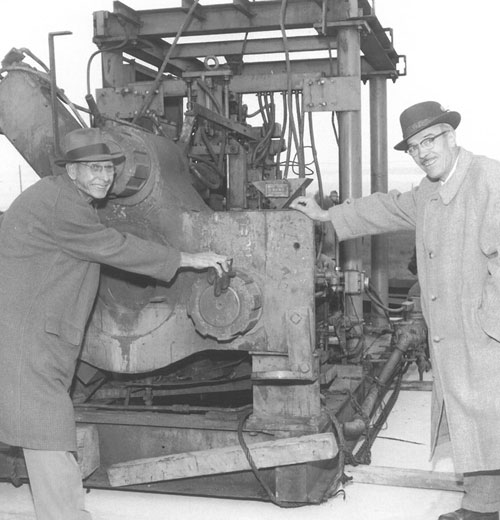

September 1962

Winnipeg-based companies E. H. Price and Acme Manufacturing formed a partnership (Price Acme of Canada Ltd), and acquired a four-inch hydraulic press used exclusively to extrude profiles for E.H. Price’s grille and register manufacturing center in Winnipeg.

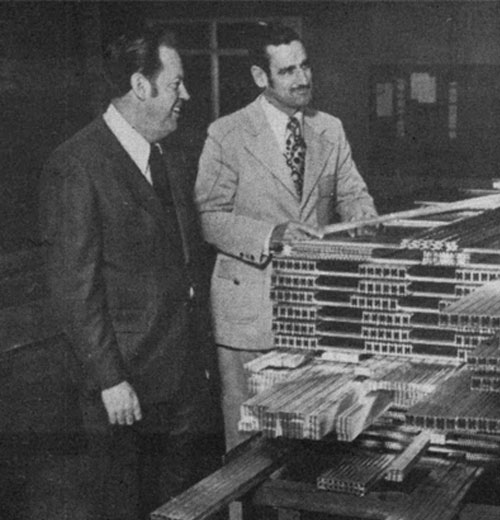

September 1972

The recognition of excess press capacity led to Price-Acme’s partnership with the Aluminum Company of Canada (Alcan) and the launch of Alcan Price Extrusions Limited (APEL), a 50/50 joint venture between the two companies to manufacture and market aluminum extrusions across the Prairie Provinces.

August 1973

A second extrusion operation was opened in Calgary, Alberta to service the growing Western Canadian market. The acquisition of a larger and more capable six-inch press in Calgary combined with the installation of a new paint line allowed for the consolidation of operations into the Calgary facility, resulting in the closure of the Winnipeg operation in 1990.

July 1994

Alcan exited the extrusion business in North America, selling its interest in APEL to the current private ownership group. Continuous upgrades to its equipment, expansion of its premises, and the installation of a new seven-inch press in 2001 (later upgraded to an eight-inch configuration) allowed APEL to grow its operations and become the supplier of preference in its chosen market.

February 2005

Further equipment enhancements and a major upgrade to its horizontal paint line have allowed APEL to further improve its capabilities and meet the AAMA2605 paint standard, which will facilitate growth and deliver superior market performance in the years to come.

May 2008

A new state-of-the-art anodizing line allowed for penetration into the architectural and commercial markets and a modern waste water handling system was installed to replace the existing 20-year-old equipment.

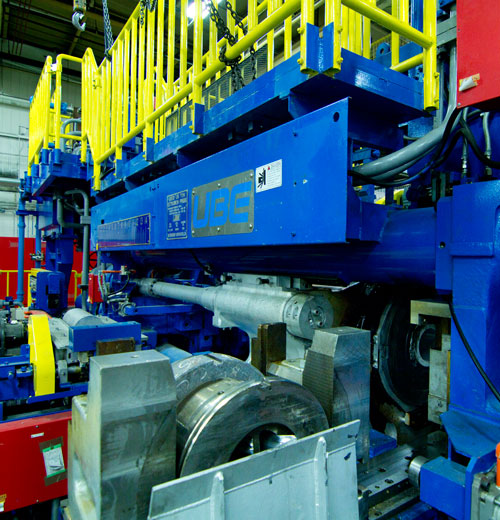

February 2010

APEL purchased the assets of Postle Aluminum North West, acquiring a three-year-old seven-inch UBE press and a facility in Springfield, Oregon. With this addition, APEL began to market its extrusions in the Western United States.

December 2011

Continuing to upgrade its capabilities, APEL replaced its 40-year-old six-inch press in Calgary with a state-of-the-art seven-inch UBE press complete with Granco Clark ancillaries.

May 2014

Additional capital investment was made to expand the business with a move into a new 135,000-square-foot facility in Coburg, Oregon which included the installation of a new nine-inch UBE press complete with Granco Clark ancillaries, a water quenching system, and an on-site material testing laboratory. The Coburg, Oregon expansion coupled with our capabilities in Calgary, Alberta make APEL one of the most modern extrusion and finishing companies located within North America.

February 2018

2018 added 60,000 square feet and a 5th press (3rd in Oregon)