Extrusions

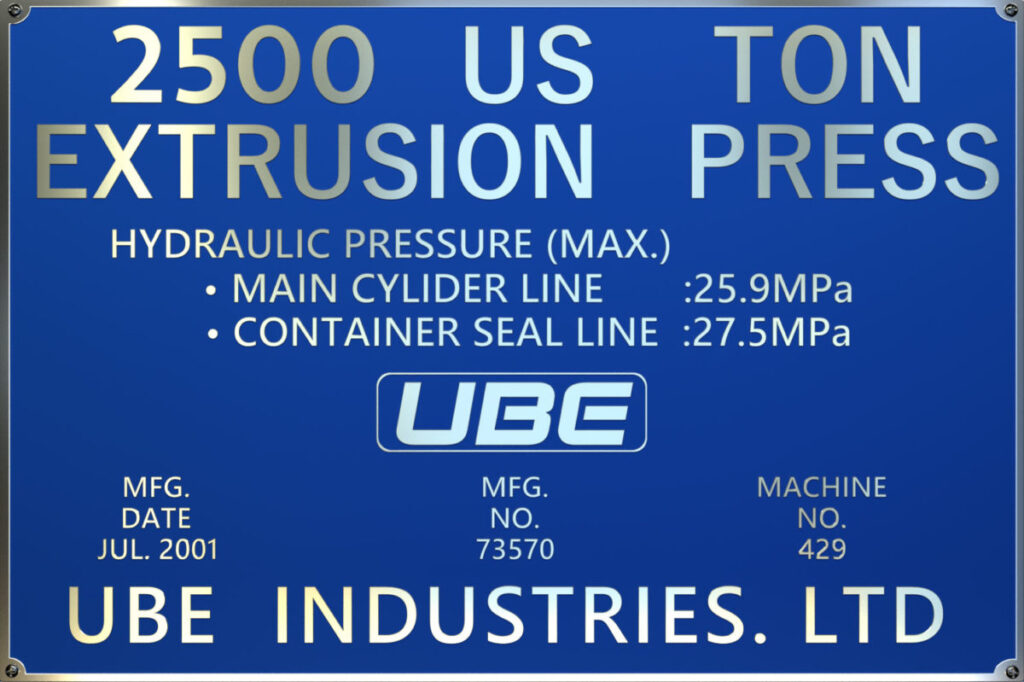

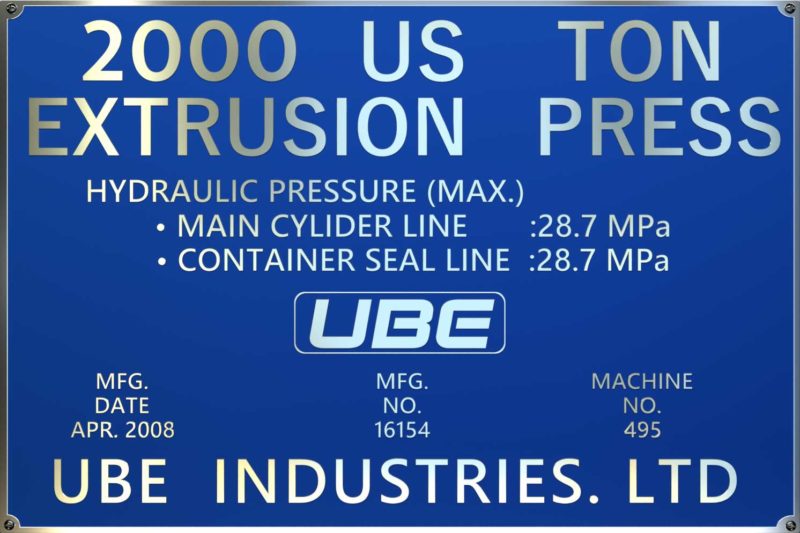

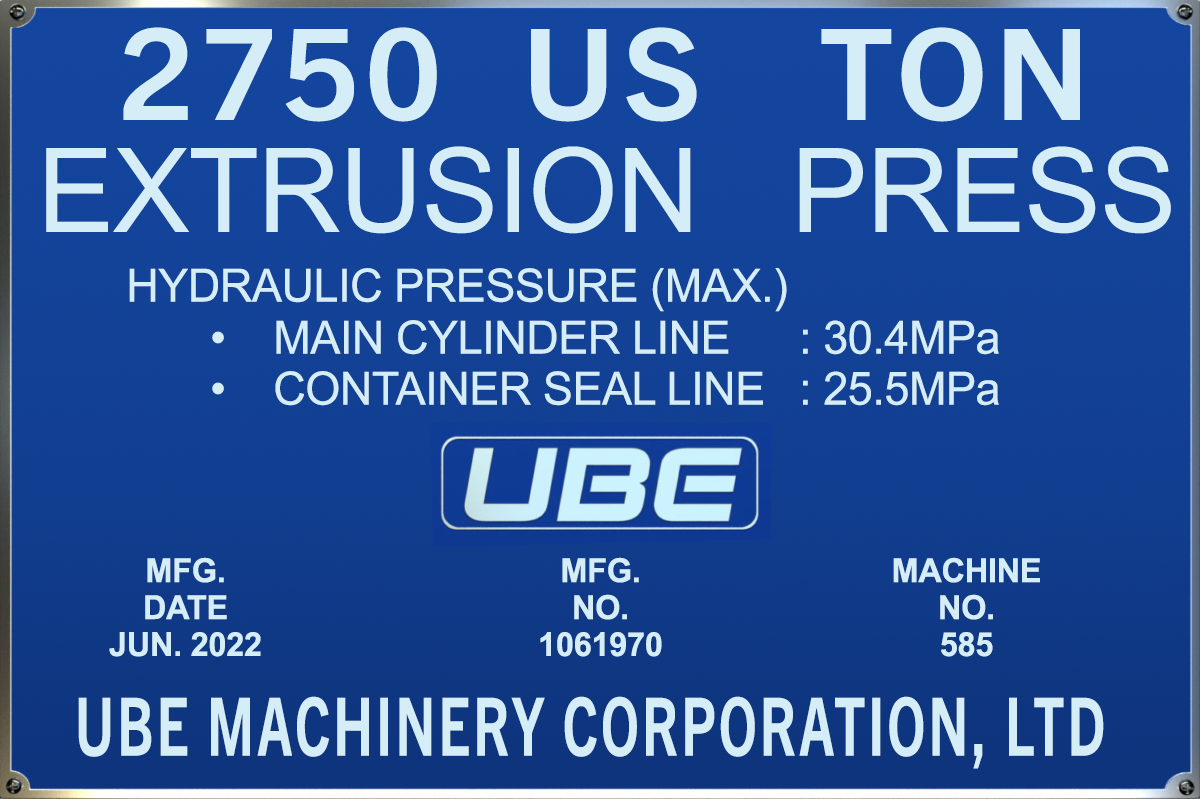

APEL houses one of the most modern fleets of extrusion presses in North America. With two presses in Calgary, Alberta, three in Coburg, Oregon and one in their new state-of-the art facility in Pheonix, Arizona, APEL is ideally situated to supply all western North American markets.