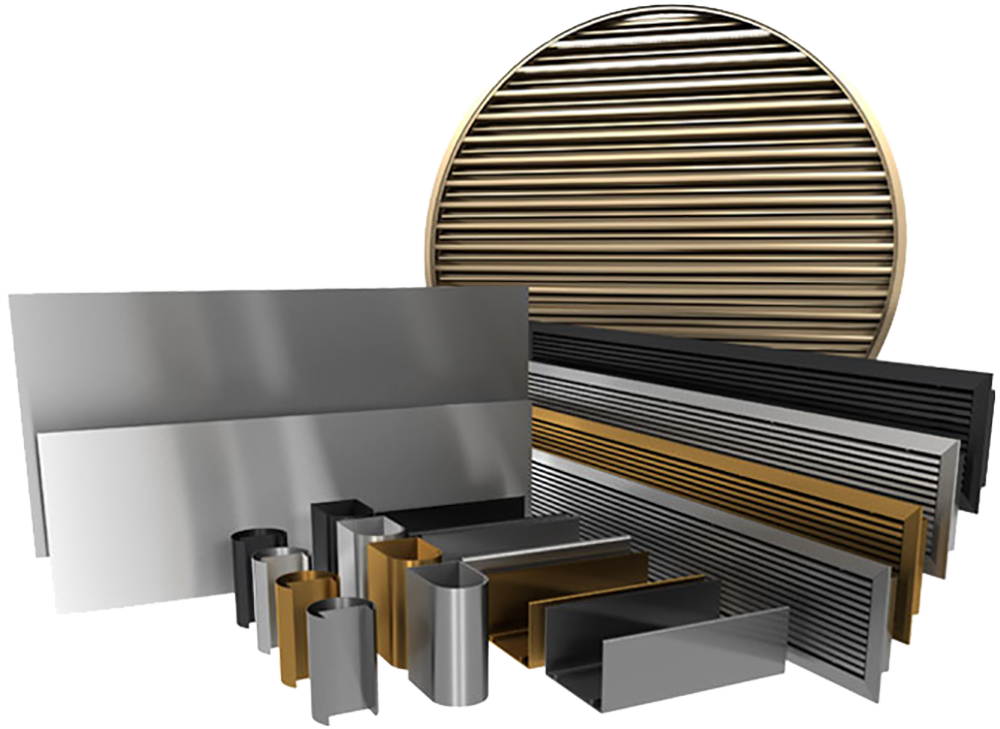

Anodizing

Our anodizing line is capable of producing clear, champagne, bronze, and black finishes in up to 24-foot 3-inch lengths meeting the American Architectural Manufacturer’s Association (AAMA) standard 611-12.

Anodizing refers to the electrochemical process that changes the surface of a metal into a corrosion-resistant, durable, and aesthetically pleasing anodic-oxide finish. This is not a process that happens before other finishing – an anodized materials’ surface is fully integrated into the aluminum substrate and cannot be chipped off or removed.

Anodizing refers to the electrochemical process that changes the surface of a metal into a corrosion-resistant, durable, and aesthetically pleasing anodic-oxide finish. This is not a process that happens before other finishing – an anodized materials’ surface is fully integrated into the aluminum substrate and cannot be chipped off or removed.

In Calgary, Apel installed a new state-of-the-art, semi-automated anodizing line in 2008 and upgraded it to provide acid etch capability in 2010. As part of this anodizing line upgrade, we replaced our aging waste treatment system with a new automated facility, ensuring 100% environmental compliance of all finishing processes.

Acid etching is an alternative to traditional caustic etching in the pre-treatment phase and can provide a superior aesthetic and more consistent finishes for repeat orders. Etching is performed on the material to minimize or entirely remove surface defects. Traditional anodizing lines use a caustic soda to mask some defects, but acid etching uses fluoride based ions that removes most surface defects while providing a clean aesthetic.

Our line is capable of producing clear, champagne, bronze and black finishes in up to 24 ft. 3 in. lengths meeting the American Architectural Manufacturer’s Association (AAMA) standard 611-12.