Extrusions

APEL houses one of the most modern fleets of presses in North America. With two presses in Calgary, Alberta and three in Coburg, Oregon, APEL is ideally situated to supply all western North American markets.

Aluminum extrusions are created from workable alloys that have been pushed through a die to produce your choice of hollow, semi-hollow, or solid shapes with high levels of accuracy and quality. Aluminum extrusion techniques make the most of the material’s unique physical characteristics, namely it’s malleability and strength. Aluminum as a material of choice is broadly used in many different applications, with many more opportunities becoming available when the aluminum is alloyed with additional metals.

APEL’s custom aluminum extrusions are the ideal choice for customers who are looking to reduce the purchase costs and overall effort in machining for their final product. The results are consistency, less material waste, and total control over your design.

From extrusions that require more basic processes – precision cutting, drilling, tapping, or punching – to fully finished products, we’ve got you covered.

Solid Aluminum Extrusion

Semi-Hollow Aluminum Extrusion

Hollow Aluminum Extrusion

CALGARY ALBERTA – EXTRUSION CAPABILITIES

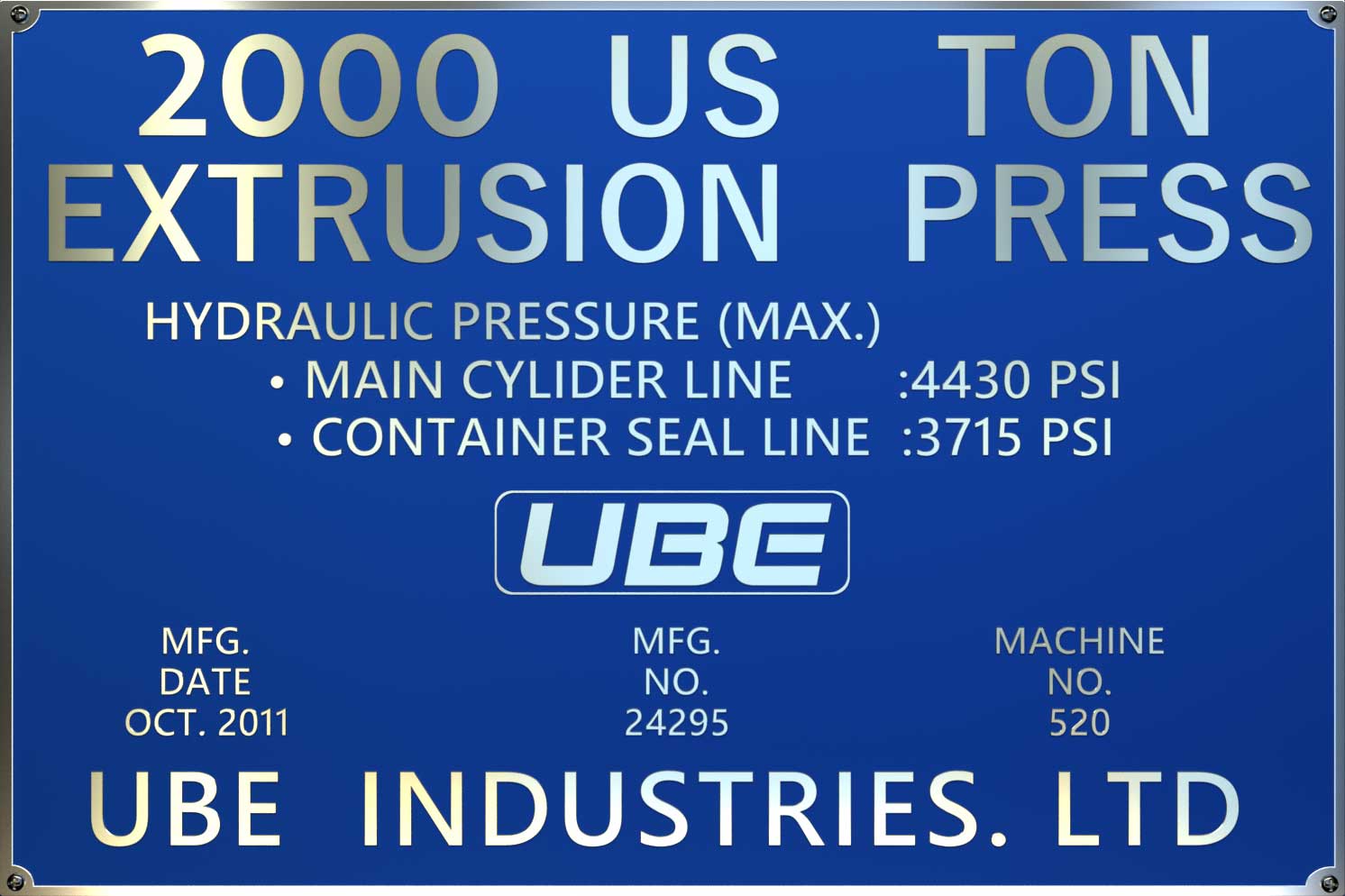

2000 ton – 7″ press

2011 UBE 2000 Ton, complete with 2011 Granco Clark handling equipment and configured to use seven-inch Log (Hot Saw).

| Minimum | Maximum | |

|---|---|---|

| C.C.D. Solids | .50″(12.70mm) | 5″(127.0mm) |

| C.C.D. Hollows | .75″(19.05mm) | 6″(152.4mm) |

| Shape Height | 1″(25.4mm) | 5″(127.0mm) * |

| Wall Thinkness (inches) | .040″(1.02mm) | .375″(9.525) |

| Pounds per Foot | 0.1′(.045kg) | 1.00′(2.54kg) |

| Length (Cut at Press) | 70.87″(1.8m) | 295.28”(9.0m)*** |

Length Tolerances: Standard Aluminum Association tolerances apply unless otherwise specified

Alloys Available: 6063 SF, 6063 B

Tempers Available: F, T-1, T-4, T-5, T-54, T-6

* The maximum C.C.D. specified restricts the height to 1″ or less.

Reducing the C.C.D. Will increases height restriction.

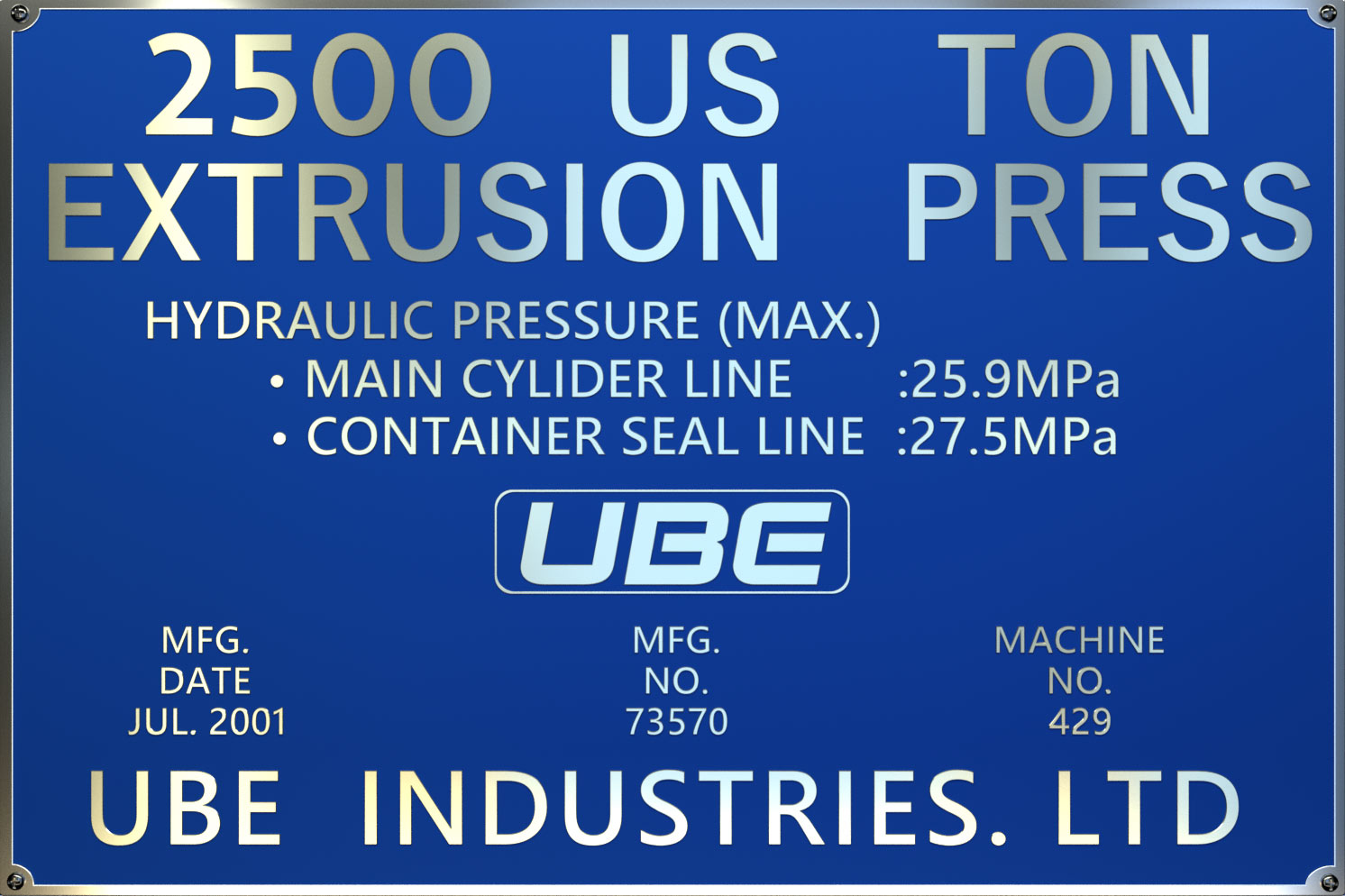

2450 ton – 8″ Press

2003 UBE 2500 Ton complete with 2003 Turla and 2009 Granco Clark handling equipment and configured to use eight-inch Log (Hot Saw).

| Minimum | Maximum | |

|---|---|---|

| C.C.D. Solids | 1″(25.4mm) | 6.50″(165.1mm) |

| C.C.D. Hollows | 1″(25.40mm) | 7″(178.8mm) |

| Shape Height | 1″(25.40mm) | 5.71″(145mm) |

| Wall Thinkness (inches) | .05″(1.27mm) | .750″(19.05mm) |

| Pounds per Foot | 0.2′(.30kg) | 2.35′(3.50kg) |

| Length (Cut at Press) | 70.87″(1.8m) | 295.28″(7.50m)*** |

Length Tolerances: Standard Aluminum Association tolerances apply unless otherwise specified

Alloys Available: 6063 SF

Tempers Available: F, T-1, T-4, T-5, T-54, T-6

* The maximum C.C.D. specified restricts the height to 1″ or less.

Reducing the C.C.D. Will increases height restriction.

COBURG OREGON – EXTRUSION CAPABILITIES

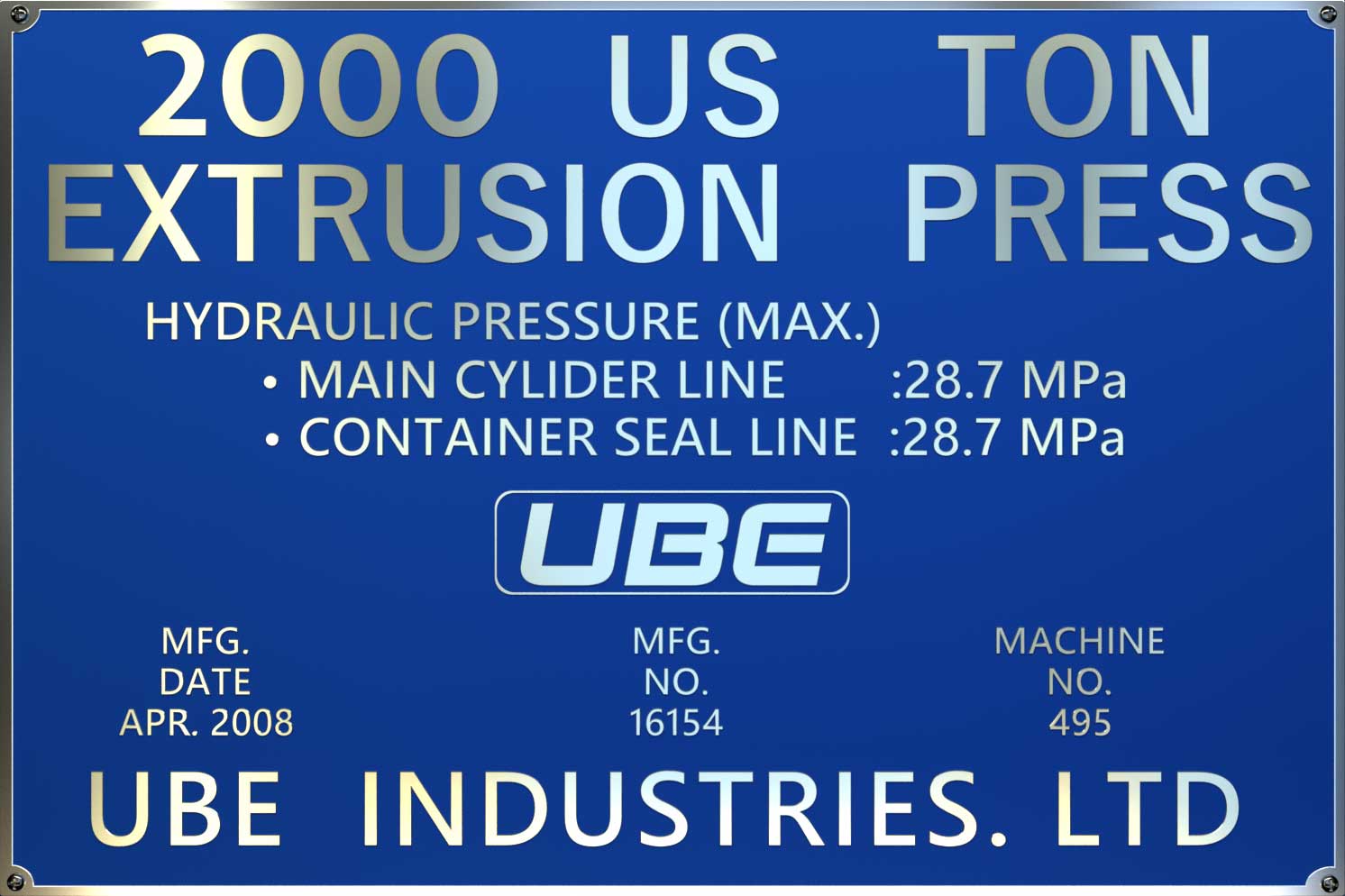

2000 ton – 7″ press

2009 UBE 2000 Ton complete with 2009 Granco Clark handling equipment and configured to use seven-inch Log (Hot Saw).

| Minimum | Maximum | |

|---|---|---|

| C.C.D. Solids | .50″ | 8″ * |

| C.C.D. Hollows | .75″ | 5″ * |

| Shape Height | .75″ | 5″ * |

| Wall Thinkness (inches) | .038″ | .375″ |

| Pounds per Foot | .09 lbs | 3.50 lbs |

| Length (Cut at Press) | 96.0″ | 480.0″ |

Length Tolerances: Standard Aluminum Association tolerances apply unless otherwise specified

Alloys Available: 6063 SF, 6005A

Tempers Available: T-1, T-4, T-5, T-52, T-54, T,-6, T-6511

* The maximum C.C.D. specified restricts the height to 1″ or less.

Reducing the C.C.D. will increases height restriction.

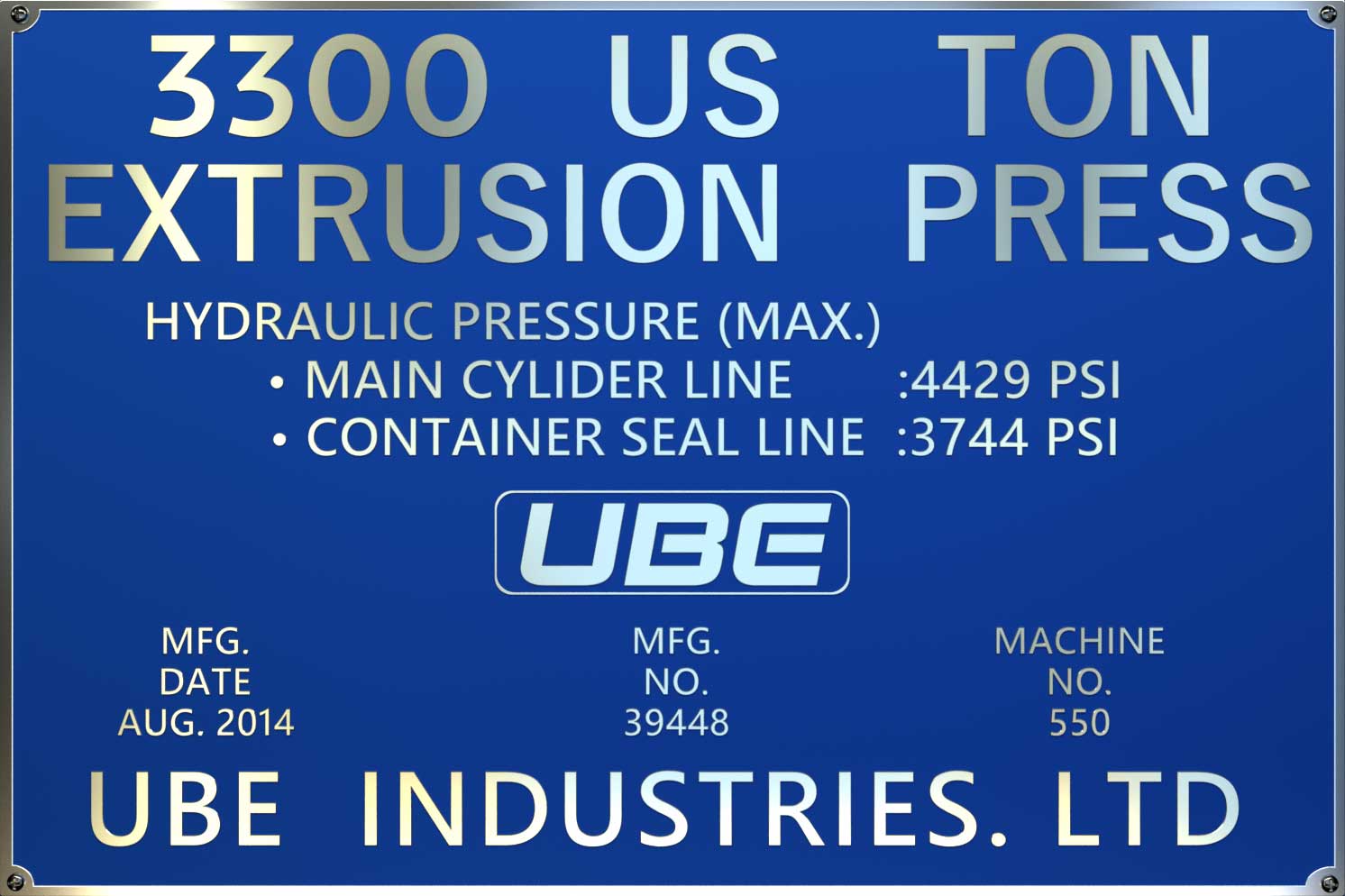

3300 ton – 9″ Press

2014 UBE 3300 Ton complete with 2014 Granco Clark handling equipment and configured to use nine-inch Log (Hot Saw), fitted with a robust, top-of-the-line water quench system.

| Minimum | Maximum | |

|---|---|---|

| C.C.D. Solids | 1″ | 10″ * |

| C.C.D. Hollows | 1″ | 10″ * |

| Shape Height | 1″ | 6″ * |

| Wall Thinkness (inches) | .05″ | .750″ |

| Pounds per Foot | 1.00 lbs | 6.00 lbs |

| Length (Cut at Press) | 96.0″ | 636.0″ |

Length Tolerances: Standard Aluminum Association tolerances apply unless otherwise specified

Alloys Available: 6063 SF, 6005A, 6061, 6351

Tempers Available: T-1, T-4, T-5, T-52, T-54, T,-6, T-6511

* The maximum C.C.D. specified restricts the height to 1″ or less.

Reducing the C.C.D. will increases height restriction.

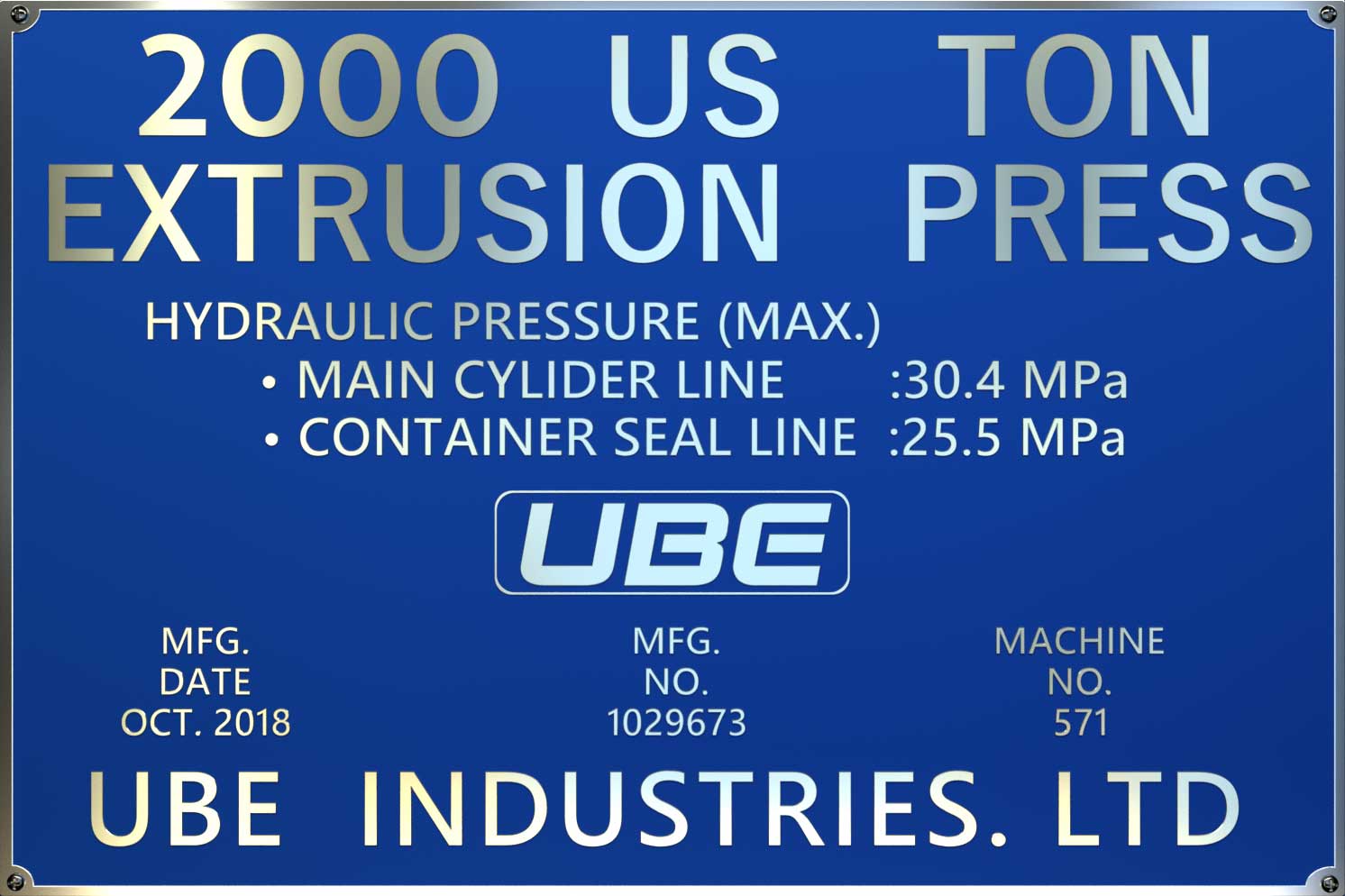

2000 ton – 7″ press

2019 UBE 2000 Ton, complete with 2019 Granco Clark handling equipment, configured to use 7-inch Log (Hot Saw).

| Minimum | Maximum | |

|---|---|---|

| C.C.D. Solids | .50″ | 8″ * |

| C.C.D. Hollows | .75″ | 5″ * |

| Shape Height | .75″ | 5″ * |

| Wall Thinkness (inches) | .038″ | .375″ |

| Pounds per Foot | .09 lbs | 3.50 lbs |

| Length (Cut at Press) | 96.0″ | 480.0″ |

Length Tolerances: Standard Aluminum Association tolerances apply unless otherwise specified

Alloys Available: 6063 SF, 6005A, 6061

Tempers Available: T-1, T-4, T-5, T-52, T-54, T,-6, T-6511

* The maximum C.C.D. specified restricts the height to 1″ or less.

Reducing the C.C.D. will increases height restriction.